Welcome to Taizhou Zhigao materials technology Co., Ltd!

Telephone: 13641587391

On June 20, the reporter learned that professor so young Kim from Ulsan Institute of science and technology, Su Mi HuR from QUANNAN University and Professor Seok Joon Kwon from Korea Institute of science and technology jointly proposed a new experimental method. Using this method, the author can get the orderly oriented block copolymer self-assembled films in the centimeter level region. After only 15 minutes of solvent annealing, the films are deficient The pit density can be reduced to about 1.37 EA / μ m2. Relevant work was published in science advanced, a subsidiary of science, under the title of "shear solvo defect annunciation of diblock polymer thin films over a large area".

The films formed by self-assembly of block copolymers have potential applications in many industrial fields. Among them, people pay special attention to the use of block copolymer self-assembly to form a large area of 10-100 nanometer ordered structure. This method has good resolution, functionality and scalability, so it is expected to break through the limitations of traditional lithography technology. However, the films formed by self-assembly usually lack the long-range order of orientation, and in large area, the defect density is high.

Directional self-assembly (DSA), including mapping epitaxy, surface chemical patterning and laser-assisted patterning, has made a milestone in the research of block copolymers with ordered nanostructures. However, DSA needs more steps, which limits its industrial application. In addition, the practical value of reducing the defects in the nano pattern prepared by DSA (such as 1 EA / cm2) remains to be proved by experiments.

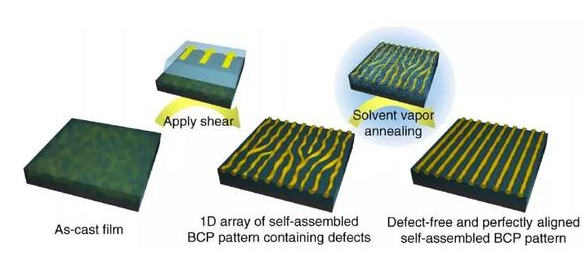

The method used by the author is as shown in Figure 1: firstly, the block copolymers are oriented by mechanical shear force, and the shear force can induce the block copolymers to arrange in a macroscopical order; secondly, the solvent steam annealing can eliminate the micro defects without destroying the long-range order induced by shear. The author calls this method shear solvo annealing or SS annealing.

Picture and text Express

(a) SEM after shearing orientation and (b) after SS annealing with toluene solvent, (c) tetrahydrofuran, (d) mixed solvent, orientation pixel after dyeing, SEM with defect number, SEM with defect area, orientation fringe after dyeing; (E) graph with annealing time of Hermans parameter P2; (f) correlation function g (R) with position The results show that: (1) the surface density of defects and the number density of defects change with the annealing time; (2) the uniformity of stripe pattern; (1) the consistency of Hermans parameter P2; (J) with the scale changes after shearing, toluene annealing, tetrahydrofuran annealing and the mixed solvent annealing.

The author invented a method of SS annealing, which can get the block copolymer film with almost perfect orientation. The influencing factors of SS annealing and the reasons of defect disappearance were analyzed by experimental and theoretical methods.